Elevate Your Offtake Revenue 10x

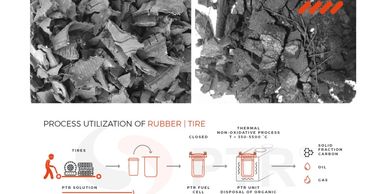

Tires

Plastics

Plastics

- SOLID (rCB) 40%

- GASEOUS (SYN) 20%

- LIQUID (OIL) 30%

- METAL 10%

Plastics

Plastics

Plastics

- SOLID CARBON 40%

- GASEOUS (SYN) 50%

- LIQUID (OIL) 10%

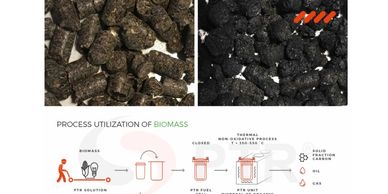

Biomass

Plastics

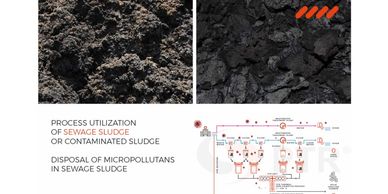

Sewage Sludge

- SOLID CARBON 40%

- GASEOUS (SYN) 35%

- LIQUID (OIL) 25%

- BIOCHAR

- BACILLUS CONCENTRATE

Sewage Sludge

Sewage Sludge

- SOLID CARBON 55%

- GASEOUS (SYN) 40%

- LIQUID (OIL) 5%

- BIOCHAR

- BACILLUS CONCENTRATE

Certifications

- Carbon Residue (rCB), solid fuel

- Gas, gaseous fuel energy

- Oil, liquid biofuel

rCB @ 90-96%

Lost Time To Extraction (LTTE) or Light Transmittance to Extraction (LTTE) delivers an incredible value of 90–96%, qualifies as excellent, and is highly sought after for high-performance applications such as premium rubber, plastics, and advanced composites.

The Brunauer–Emmett–Teller (BET) surface area of 100–400 m²/g is classified as the highest grade, delivering maximum reinforcing properties and compatibility for applications that require excellent dispersion, strength, and composite adhesion. This specification is critical in rubber manufacturing, advanced polymers, and high-value composite materials.

Intelligent Resource Recovery Solutions

Transforming waste resources into viable commidities and energy

Resource recovery is a circular economy as it maximizes the value extracted from waste, recovers secondary raw materials and energy, diverts non-recyclable items from landfills, and supports resource efficiency, all while reducing greenhouse gas emissions and environmental risks. It helps close the loop by ensuring leftover waste feeds back into the system as energy or materials rather than polluting the environment and our water systems.

Our Process

A Turnkey Path to W2E

One Step at a Time with the End in Mind

Develop

Site evaluation, feasibility studies, and project design

Finance

Secure 100% funding options and revenue share program

Construct

Efficient and timely installation in 4-6 months

Supply

Equipment procurement and logistics

Operate

Long-term management, support, and monitoring

Partner

Collaborate on future renewable opportunities

"If you can't describe what you are doing as a process, you don't know what you're doing." - W. Edwards Deming

Contact Us

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.